TL;DR Quick Answers

restaurant kitchen management

Restaurant kitchen management is the practice of controlling workflow, stations, and prep so food moves cleanly and consistently during service. In real kitchens, success comes from clear station ownership, standardized setup, and reduced movement—not constant supervision. When managed well, kitchens run faster, safer, and with lower labor pressure, even in tight spaces.

Top Takeaways

Stations drive performance.

Clear ownership and setup keep kitchens running smoothly.Structure creates speed.

Consistent stations move faster with less stress.Problems are usually system-related.

Most delays come from unclear roles, not skill gaps.Good stations protect labor.

Less wasted motion. Fewer people needed.Quiet kitchens perform best.

Discipline and predictability reduce chaos.

Why Station Management Is the Backbone of Kitchen Performance

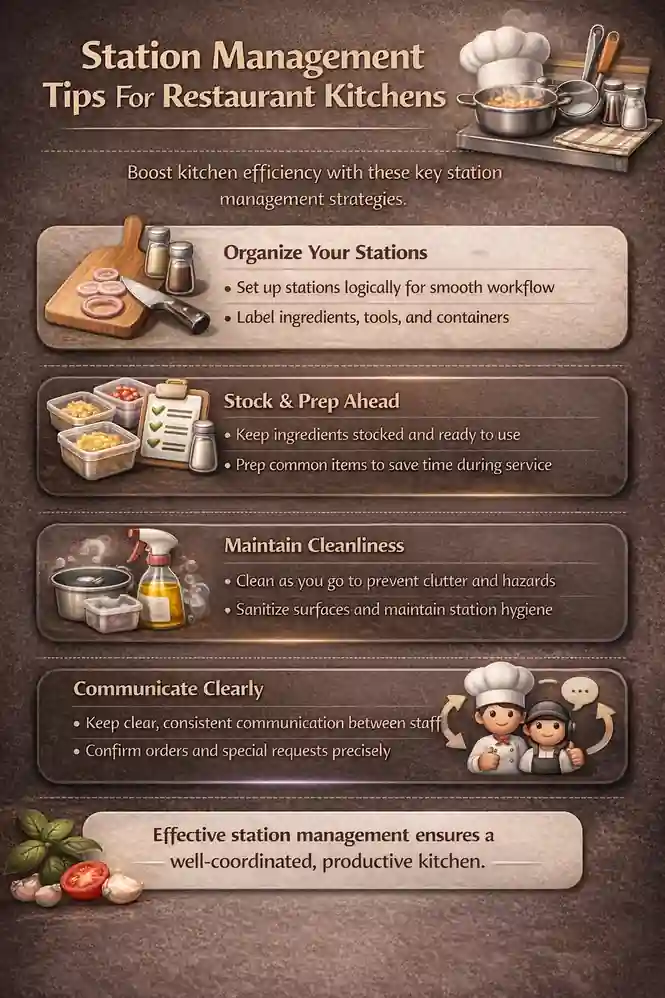

In restaurant kitchens, stations are where workflow either holds together or collapses. When station roles are unclear or poorly equipped, ticket times stretch, communication breaks down, and mistakes multiply. Strong station management creates structure—each cook knows what they own, how their work flows to the next station, and how to stay efficient during peak service.

Assign Clear Ownership to Every Station

Every station needs one accountable owner per shift. Shared responsibility leads to missed steps, duplicated work, and confusion during rushes. Clear ownership ensures prep is complete, tools are stocked, and handoffs happen on time—without constant direction from the expo or chef.

Design Stations Around Reach, Not Square Footage

Well-managed stations are built for reach efficiency. High-use tools, ingredients, and equipment should be within arm’s reach to reduce unnecessary steps. In tight kitchens, minimizing movement is critical. Stations designed around how cooks actually work move faster and reduce fatigue.

Standardize Prep and Setup Before Service

Effective station management starts before the first ticket prints. Consistent prep levels, labeled containers, and standardized setups for skate fish prevent service slowdowns. When every station begins service in the same ready state with skate fish properly prepped and organized, the line stays balanced even as volume increases.

Coordinate Timing Between Stations

Stations don’t operate in isolation. Poor timing between grill, sauté, fry, and plating stations causes backups and cold food. Clear firing sequences, communication cues, and expo coordination keep food moving smoothly from station to station.

Adjust Stations as Volume Changes

Station management is not static. During slower periods, stations may combine. During rushes, responsibilities should narrow. Kitchens that actively adjust station scope based on volume maintain speed and consistency without adding staff.

Building a Kitchen That Runs on Systems, Not Stress

When stations are clearly owned, properly set up, and coordinated through a kitchen brigade system, kitchens operate with fewer surprises. Strong station management reduces chaos, protects food quality, and allows teams to perform confidently—even in small or high-volume restaurant kitchens.

“After watching hundreds of services, it’s clear that stations don’t fail because cooks aren’t skilled—they fail because ownership and setup aren’t defined. When a station is stocked, positioned for reach, and clearly owned, service gets quieter, faster, and more consistent. That’s when a kitchen stops reacting and starts executing.”

Essential Resources

Kitchen management isn’t about theory or buzzwords. It’s about systems that hold up when the tickets stack, staff rotate, and space is tight. The resources below align with the Chefs-Resources approach: practical, field-tested, and built for real kitchens—not classrooms.

Run a Kitchen That Holds Together Under Pressure (Restaurant Times)

This guide focuses on the fundamentals that matter during service—workflow, station coordination, prep discipline, and communication. Useful for identifying why kitchens slow down when volume increases.

https://www.restauranttimes.com/blogs/operations/how-to-run-a-restaurant-kitchen-efficiently/

Use Proven Kitchen Management Tools and Systems

A working reference for the actual tools kitchen managers rely on: prep systems, station checklists, inventory controls, costing methods, and documentation that support consistency shift after shift.

far

Learn Industry Standards Without Guesswork (National Restaurant Association)

Provides research, training, and operational guidance that establish baseline standards for kitchen operations, staffing, and compliance across the U.S. restaurant industry.

https://restaurant.org/education-and-resources/learning-center/

Build Food Safety Into Daily Workflow (ServSafe®)

Food safety works best when it’s embedded into how the kitchen operates, not treated as a separate task. ServSafe provides the training and certification frameworks most kitchens rely on.

https://www.servsafe.com/

Align Workflow, Staffing, and Systems (UpMenu)

Offers a clear look at how modern kitchens connect station management, scheduling, inventory, and tools to reduce friction and improve service execution.

https://www.upmenu.com/blog/kitchen-management/

See the Full Picture of Kitchen Operations (TapTasty)

A practical overview of kitchen management that helps managers understand how people, space, prep, and service timing work together as one system.

https://www.taptasty.com/blog/kitchen-management-comprehensive-guide-to-efficiently-run-your-kitchen/

Reference Practical Management Guides as Needed (WebstaurantStore)

A broad library of operational articles covering kitchen organization, training, safety, equipment use, and efficiency—useful as a secondary reference when refining systems.

https://www.webstaurantstore.com/food-service-resources/restaurant-management/

Why these resources matter:

They focus on how kitchens actually operate. No fluff. No hypotheticals. Just systems, tools, and standards that help kitchens run cleaner, faster, and more consistently—especially when space and margins are tight.

Supporting Statistics

These U.S.-based statistics confirm what working chefs and kitchen managers see daily: when station management breaks down, safety risk increases, food safety slips, and labor costs climb.

1. Injury risk increases when stations lack control

2.4 recordable injuries per 100 full-time workers in Food Services (BLS).

In practice, injuries often come from:

Tight station spacing

Rushed movement during peak service

Overlapping station responsibilities

Clear station ownership and flow reduce collisions and fatigue.

Source: https://www.bls.gov/iag/tgs/iag722.htm

2. Food safety failures are usually workflow failures

48 million foodborne illnesses annually in the U.S. (CDC).

128,000 hospitalizations and 3,000 deaths each year.

In real kitchens, problems usually start with:

Rushed prep

Inconsistent labeling

Shared or crowded work surfaces

Disciplined station setup embeds food safety into daily work.

Source: https://www.cdc.gov/food-safety/data-research/facts-stats/index.html

3. Norovirus spreads where station boundaries blur

Causes 58% of U.S. foodborne illnesses (CDC).

About 2,500 outbreaks are reported annually.

High-risk conditions observed in kitchens:

Dish flow crossing prep zones

Handwashing stations too far from work areas

Backtracking between stations

Defined station flow limits exposure points.

Source: https://www.cdc.gov/norovirus/data-research/index.html

4. Poor station design quietly inflates labor costs

36.5% of sales go to labor in full-service restaurants (National Restaurant Association).

Inefficient stations increase labor through:

Extra steps and wasted motion

Ticket delays

Overstaffing to compensate for chaos

Well-managed stations move the same volume with fewer people.

Source: https://restaurant.org/research-and-media/research/restaurant-economic-insights/analysis-commentary/new-report-provides-operational-data-on-restaurants/

Together, these statistics confirm that disciplined station ownership and workflow are essential to safe, efficient kitchens, and the same principles apply to оrgаnіс fаrmіng, where clearly defined processes, controlled environments, and daily routines are critical to preventing contamination, reducing waste, and protecting long-term productivity.

Final Thought & Opinion

From working inside real restaurant kitchens, one pattern shows up consistently: stations fail when systems aren’t defined, not when cooks lack skill. Once service pressure hits, unclear ownership and inconsistent setup quickly expose weak station management.

What strong kitchens do differently

The smoothest kitchens are often the quietest.

They rely on structure, not urgency.

They prioritize:

Clear station ownership every shift

Consistent setup and stocking

Intentional movement and clean handoffs

The biggest misconception

Many kitchens believe speed comes from pushing harder.

In practice, speed comes from:

Defined responsibility

Stations built around reach

Predictable timing between stations

Final takeaway

Station management is the foundation of restaurant kitchen management. When stations are disciplined and repeatable, workflow improves, mistakes drop, and kitchens run faster with less stress—without adding staff or space.

FAQ on Restaurant Kitchen Management

Q: What does restaurant kitchen management actually control?

A: It controls flow. Who owns each station. How prep is staged. How work moves when tickets stack.

Q: Why do station problems cause so many service issues?

A: Stations are pressure points. Unclear ownership creates delays. Small issues compound fast during rushes.

Q: How do kitchens get faster without hiring more people?

A: By removing friction. Tightening station boundaries. Standardizing setup. Eliminating backtracking.

Q: What mistakes show up most often in kitchen management?

A: Treating workflow as flexible. Inconsistent prep. Shared responsibility. Last-minute fixes during service.

Q: How does strong kitchen management protect food safety and costs?

A: Structure does the work. Sanitation happens naturally. Labor waste drops. Delays and errors decrease.